Conversion Technologies

We have the right tools for your job

Reprographics

Repro is an essential part of our printing process, we have a fantastic artwork management team who ensure our customers’ requirements are met and understood from design concept, artwork, and production, using advanced plate technologies and colour management systems providing technical support where required.

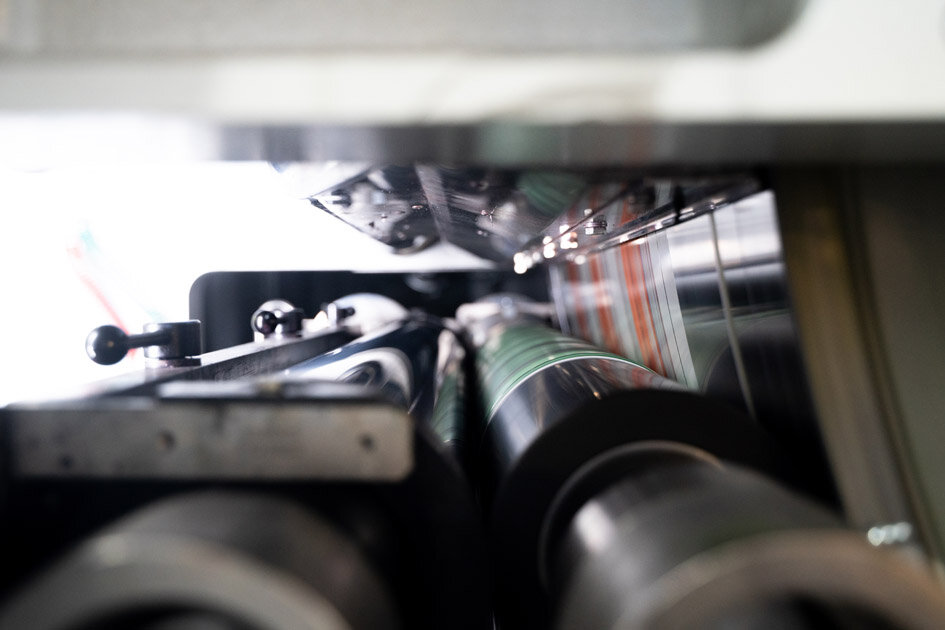

Flexographics printing

We have two state of the art wide web flexographic printing presses, capable of printing up to 1280mm wide, in 8 colours, reverse or surface print, using technical print varnishes such as Matt & Tactile. We can also pattern apply matt lacquers, for the matt/gloss effect, as well as slitting in line for larger OD reels.

Lamination

We can laminate using solvent-free adhesive for duplex or triplex laminate structures, using many different film materials and combinations, we also warm room cure all our laminated products to ensure they are compliant and sufficiently cured before dispatching.

Micro & Macro Perforation

We have multiple units of different perforation techniques to support both the fresh produce markets and the bakery markets. We can hole punch in a variety of patterns with 8mm holes, we can hot needle perforate from P1 to P30 in 25/50mm strips, we can pattern apply laser perforation for respiratory requirements or ‘easy tear’ applications.

How can we help?

If you would like to discuss our capabilities, we’re more than happy to talk you through our processes.